A photo of the Bang Bang Boom Box (B⁴), our hardware testing apparatus

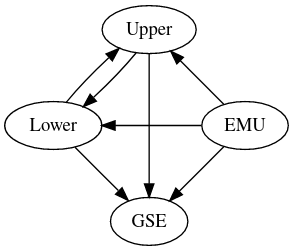

Take a look at the avionics system design and

PSPieChart posts to get context on this document.

This document is a direct continuation of Avionics System Design and details information about flight and GSE software for Purdue Space Program Liquid's next rocket, the CraterMaker Special.

Flight Software

Development Environment

The RP2040 has a very well-documented and easy-to-use SDK written in C.

Everything can be configured to CMake.

The first step to start developing software for the rocket was determining the

source tree organization and writing a build system.

I decided on using a single CMakeLists.txt at the project root so that it'd be

easier for new members to work without worrying too much about the build system.

The build process also includes ccache for insanely clean builds.

This is how the source code is organized

PSPL_CMS_Avionics_Code/

├── README.md <- This file

├── src/ <- contains main programs for each board

│ └── someprogram/ <- Main program folder, i.e., for a board

│ ├── someprogram.h <- All header stuff for this program

│ ├── main.c <- Contains the entrypoint

│ └── other.c <- Other source files

├── lib/ <- common libraries shared by all boards

│ └── example/ <- example library

│ ├── example.c

│ └── include/ <- header files, added to include path

│ ├── example.h <- top level header, included with `#include <example.h>`

│ └── example/ <- secondary headers

│ └── whatever.h <- included with `#include <example/whatever.h>`

├── external/ <- Gitignored, for automatically downloaded libraries

├── include/ <- Global include directory, used for configs and stuff

├── build/ <- not uploaded to the repo, contains compilation outputs

│ └── bin/ <- contains the files to be uploaded to the boards

├── .clang-format <- file containing autoformatter rules

├── .gitignore <- file containing things to not be uploaded to GitHub

├── Doxyfile <- Doxygen Documentation Generator Configs, mostly autogenerated

├── CMakeLists.txt <- Main build script

└── Makefile <- User-friendly build script, calls CMake

Finally, there's a top-level Makefile which handles dependencies, compilation,

and generating the compilation database (for intellisense)

Though Doxygen is used for generating documentation, it's not commonly

used, and we usually just refer to the docstrings.

The dependencies for flight software development are very minimal, needing only

ARM GCC and newlib to get started. And as of writing this, everything clean

builds (with ccache cleared) in under 15 seconds.

Peripheral I/O

The main peripherals on this rocket are ADCs, storage devices, radios, Ethernet

(more on this later), and digital output for pyro channels.

Digital outputs are easy enough, pico-sdk has all the code infrastructure

needed for that.

One of the requirements we have for peripherals on the rocket, which most of our

selected parts comply, is that they communicate over SPI.

SPI is a fantastic protocol and can be abstracted away to the level of

selecting a peripheral, and sending and receiving a bitstream to the peripheral

at a specified rate.

The process of writing the drivers themselves is mostly straightforward -

implement the protocols that the chip manufacturers specify in the datasheet.

The first version of the driver is always a fully synchronous version, i.e., all

communication with the device is commanded by the main thread. This makes it

easy to meet deadlines when it comes to upcoming tests.

The next step is implementing interrupt-driven I/O. For our purposes, this isn't

necessary 99% of the time, but it becomes a problem whenever we run any

long-running subroutines. On the hardware side, DRDY's from peripherals are

connected to a GPIO pin, which can be used to trigger a subroutine, to say, read

data off of an ADC and add it to the queue to be stored and transmitted.

Implementing DMA isn't really at the highest priority though - the only place

where it's applicable would be the Ethernet and Flash drivers. Devices

like the ADC read short bursts of data triggered by interrupts, and we decided

that it's not worth the effort to implement DMA for these devices.

Fun fact: the RP2040's DMA system is turing complete. More info

here

Network Stack

The network stack was nicely handled for us by the W5500 chip,

which is what we use to add Ethernet capability to the RP2040. Communicating

over SPI, it includes a hardwired TCP/IP stack, with 6 sockets.

All we need to do is write a driver to access this functionality, and abstract away details such as socket creation, buffer management, configuration, etc. I won't be going into much detail about this driver, but you can read the datasheet for the chip here

Communication Protocols

This is where the fun begins

This is where the fun begins

At the launch site, the rocket, the GSE system (Black Cat Launch System, BCLS),

and the launch operators' computers are all connected over

Ethernet.

While the rocket is on the ground, there are two primary requirements for

communication with the rocket.

- We need live sensor data to be available to operators

- We need remote procedure call capability

The EMU board is fully responsible for the launch countdown and autosequence of

this rocket, so RPC capability is important.

But first - how do we stream live sensor data from the boards to each other and

the ground?

My solution - SensorNet. The concept is very simple, it starts with this

struct definition.

SensorNet

typedef struct {

u16 sensor_id; // globally unique

u64 time; // microseconds since UNIX epoch

u64 counter; // per sensor

i64 data;

} sensornet_packet_t;

The system is very straightforward - take one or more of these packets, put them

on a UDP packet, and send them on their merry way.

Decoding is simple enough. If it's another flight board decoding, it just has to

cast the packet it read to sensornet_packet_t*. On the ground side, just

manually decode the binary data. There are plenty of libraries for most

programming libraries to handle this.

Doing things this way has the blazing fast serialization time of 0ms.

On the networking side of this - each flight board (EMU, LFC, UFC), will have a

UDP multicast group IP assigned to it, and any devices interested in data from

that board can simply open a socket listening to that multicast IP.

CommandNet

Now this is slightly more complicated.

I concluded that we need two features from CommandNet

- The ability to directly set the values of certain variables

- The ability to call functions that don't have any parameters.

I see this as basically a more complicated version of the "set registers, run

instruction" model.

In order to simplify the implementation of both sides of this protocol, I

decided to go with MessagePack, which is a JSON-like binary format for

serializing information. Neither throughput nor latency was an important factor

for this application, so we prioritized simplicity. These packets would then be

sent over a TCP connection to the rocket.

This is the protocol "spec":

Request-response protocol for sending commands over a TCP socket

Request format:

[request type(u8), args...]

EXEC_CMD: [EXEC_CMD, command name]

ALL_CMDS: [ALL_CMDS]

SET_VAR: [SET_VAR, variable name, value]

GET_VAR: [GET_VAR, variable name]

ALL_VARS: [ALL_VARS]

Response format:

[status(u8), args...]

EXEC_CMD: [status(SUCCESS/ERROR)]

ALL_CMDS: [status(SUCCESS/ERROR), [command 0 name, ...]]

SET_VAR: [status(SUCCESS/ERROR), old value]

GET_VAR: [status(SUCCESS/ERROR), value]

ALL_VARS: [status(SUCCESS/ERROR), [[var 0 name, var 0 value], ...]]

All names are strings (I know, strings are evil), and all values are 64-bit

integers.

A full CommandNet exchange would take place as follows:

+---------+ +---------+

| Client | | Rocket |

+---------+ +---------+

| |

| Open TCP Socket |

|---------------------->|

| |

| Send request |

|---------------------->|

| |

| Send response |

|<----------------------|

| |

| Close TCP Socket |

|<----------------------|

| |

+---------+ +---------+

| Client | | Rocket |

+---------+ +---------+

The way the network at the launch site is set up, it's possible that

people outside our team can plug into the network and send packets to the

rocket - this isn't a problem we expect to encounter, but it's one we have to be

ready for anyway.

To solve this, we simply add AES256-CBC symmetric key encryption, with a key

derived from a passphrase.

Now, instead of sending the bare MessagePack encoded packet, we send a

base64-encoded ciphertext. The reason for using base64 is so that it's easy to

know where a transmission ends by just checking if there's an endline.

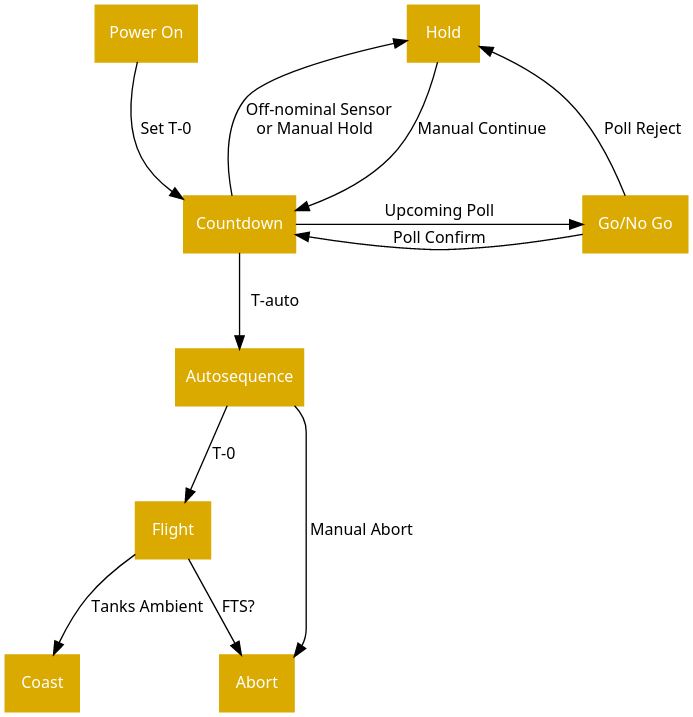

EMU State Machine

The state machine is a failsafe method of performing launch control.

Interacting with this state machine is the primary objective of CommandNet. It

looks like this:

Most of the time launch will be spent in the Countdown - Go/No Go loop.

At preset points in the countdown, the launch operators will need to issue a

Go/No Go to the current poll. If the poll either times out or a "No Go" is

issued, the countdown is placed on hold until manual intervention.

The countdown also automatically goes on hold if there's an off-nominal

situation, whatever that may be.

If all goes well, and the final poll is answered, the state machine goes into

autosequence at a set point in the countdown (T-auto).

In this case, if communication with the rocket is lost before autosequence

starts, the rocket will not launch.

The autosequence phase contains the ignition sequence. A manual abort can be

issued during the autosequence, which would place the vehicle in a safe state.

DevOps

Back to the boring stuff.

All this software needs to be tested on actual hardware, and it's inconvenient

and expensive for everyone working on software to have test hardware.

To solve this problem, Taylor

devised the Bang Bang Boom Box, the picture at the start of this page.

The box contains a Raspberry Pi which is connected to whatever board is

currently being worked on, through USB and GPIO lines to the RESET and BOOTSEL

pins.

The source files include simple scripts which can then flash binaries to the

board. The RP2040 has a UF2 ROM bootloader, so when it's RESET with BOOTSEL held

active, it shows up as a USB storage device, and the firmware file can be copied

into it to write it to device flash.

The flight software can be compiled either on the Pi itself or copied over.

The Pi is added to a tailscale network, so it can be

securely accessed anywhere there's internet.

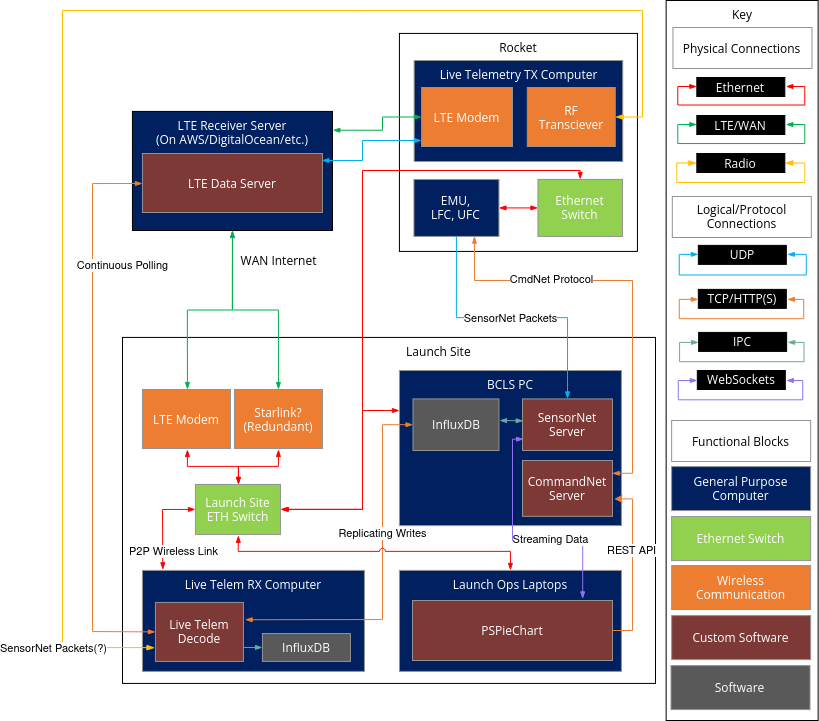

GSE Software

This basically comes down to implementing everything in this data path diagram.

Every maroon block in this image is a separate piece of software that needs to

be written.

These are the ones with development underway

PSPieChart

See this post

SensorNet Server

This is a very crucial piece of software with this core requirement

- Log every single SensorNet packet that hits its socket

We selected NodeJS as the platform for this because it made it easy to integrate

REST endpoints for setting and retrieving sensor calibrations, and to add

WebSocket support so that packets can be forwarded to PSPieChart.

We also decided on using InfluxDB as the timeseries database, because it's

popular and fits our needs.

This server includes endpoints to configure sensor ID to name mappings,

calibrations, custom expressions for derived data, and retrieval of historical

data.

CommandNet Server

This is just a Python implementation of the protocol, with a REST API.